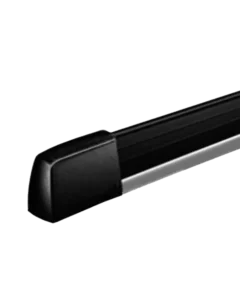

DTE - Safety Edge 35x75mm Mechanical Safety Edge

Taught wire safety edges are a simple mechanical method for detecting pressure along a rubber extrusion. Though the form is for from attractive, a consideration on domestic gates, the deep deformation of the rubber provides superior protection.

A wire inside the leading edge of the rubber extrusion is held in tension. Any pressure on the rubber pulls on the wire operating the microswitch. Special two rotating end supports make the safety edge sensitive to side loads as wel

A second “fail safe” microswitch monitors the wire for breakage. The resultant output is a single N/O contact. An 8K2 resistor can be fitted for 8K2 inputs. No power is required, so a 2 core cable is sufficient. The DTR may be used to make a wireless safety edge.

DTE215, DTE220, and DTE225 are 1.5m, 2.0m and 2.5m safety edges. They are easily cut down to shorter lengths, but the tension in the wire needs to be rest correctly. More than safety edge can be wired together in series, with appropriate adjustment for 8K2 resistors.